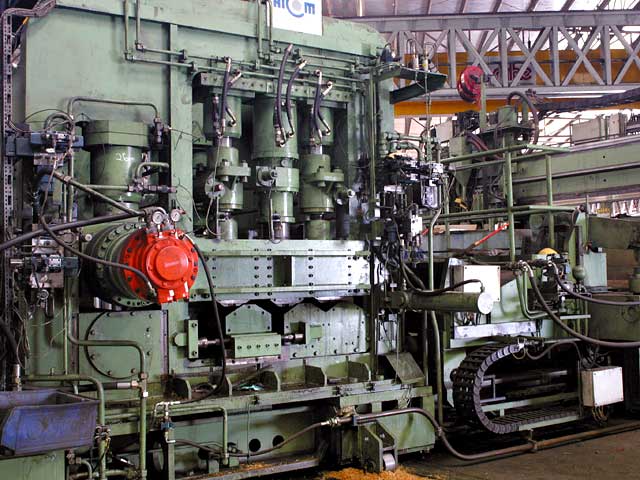

Pipe Mills and Equipment

Henry Engineering has extensive experience in designing and commissioning pipe mill plant and equipment.

Pipe mill experience started with NZ Steel Pipe in the early 90s. Henry Engineering designed and fabricated for NZ Steel Pipe an extensive range of pipe mill equipment.

This service continued for Hicom Petro Pipe (Malaysia), the pipe mill that effectively produced over 1000 kms of API gas pipe for Peninsula Malaysia . Henry Engineering was involved in ensuring the company operated effectively on a daily basis and provided ongoing staff training. Henry Engineering designed and installed a range of pipe mill equipment, managed local fabrication, and implemented numerous enhancements including SAW control systems and weld seam tracking systems.

Following, Henry Engineering commissioned a leading off-line API pipe mill in India managing to successfully form and tack-weld pipe at 10 meters/min, making it the fastest producing helical pipe mill in the world.

In essence if you have a need for expertise to:

- evaluate and select plant and equipment.

- develop an effective plant layout.

- enhance your existing pipe mill operation, reduce defects.

or for:

- proven designs for equipment .

- training on effective mill operation including:

- weld parameter optimization.

- pipe forming setting and control.

then call us.